Ok, so I have found some time to put up a couple videos in which I show my two main test programs. If you go to YouTube to watch the clips, there is a bit more information about how the program actually works.

The first program is my latest try, and after you watch the video I will give you the code. Here it is:

And here is the code:

#include [Servo.h]

Servo Tilt; Servo Turn;

int pos = 100, GKLpos = 0, GKL = 0, smthns = 10;

int thresh = 75, allwnc = 10, drkst;

void setup()

{

Tilt.attach(9); Turn.attach(8); pinMode(4, OUTPUT);

Tilt.write(180); Turn.write(pos); drkst = analogRead(0);

}

void loop()

{

int AR_0;

drkst = analogRead(0);

digitalWrite(4, HIGH);

// Right / Left

for(pos = 150; pos > 0 + smthns; pos = pos - smthns)

{

Turn.write(pos);

delay(150);

AR_0 = analogRead(0);

if(AR_0 > GKL)

{

GKLpos = pos;

GKL = AR_0;

}

}

Turn.write(GKLpos);

delay(50);

GKL = 0;

GKLpos = 180;

// Up / Down

for(pos = 180; pos > 10 + smthns; pos = pos - (smthns*2))

{

Tilt.write(pos);

delay(150);

AR_0 = analogRead(0);

if(AR_0 > GKL)

{

GKLpos = pos;

GKL = AR_0;

}

}

Tilt.write(GKLpos);

GKL = 0;

GKLpos = 180;

delay(1000);

AR_0 = analogRead(0);

if(AR_0 > drkst + thresh + allwnc)

{

while(analogRead(0) > AR_0 - allwnc);

}

else delay(2000);

}

Here is the video of the program I did before that one, you will notice that once it loses the light, it takes a while to find it again, but if the light sensor is kept in the rotational axis, the can robot can find it again much quicker than in the previous program.

And here is the code for that program:

#include [Servo.h]

Servo Tilt;

Servo Turn;

int thresh1 = 750,

pos = 0, smthns = 3,

pos2 = 180;

int cont = 0, M;

int ftx = 1;

void setup()

{

Tilt.attach(9);

Turn.attach(8);

pinMode(4, OUTPUT);

Serial.begin(9600);

pos = 0;

Tilt.write(pos2);

Turn.write(pos);

}

int forctr = 0;

void loop()

{

//Find the x axis.

for(cont = 0; cont < 1; cont++){

digitalWrite(4, HIGH);

for (M = 180; pos < M - smthns;)//turn left

{

if (analogRead(0) < thresh1)

{

pos = pos + smthns;

Turn.write(pos);

delay(smthns * 10);

}

else

{

M = pos + 20;

while(analogRead(0) > thresh1)

{

analogWrite(A2, 200);

delay(500);

analogWrite(A2, 20);

delay(200);

}

}

}

delay(100);

for (M = 15; pos > M + smthns;)//turn right

{

if (analogRead(0) < thresh1)

{

pos = pos - smthns;

Turn.write(pos);

delay(smthns * 10);

}

else

{

M = pos - 20;

cont = cont - 1;

while(analogRead(0) > thresh1)

{

analogWrite(A2, 200);

delay(500);

analogWrite(A2, 20);

delay(200);

}

}

}delay(500);}

//find y.

if (pos2 > 10 + 40)

{

pos2 -= 40;

Tilt.write(pos2);

}

else{pos2 = 180; Tilt.write(pos);}

}

P.S. I recognize that by posting my code to the public, I have given you the permission to use and modify to any extent the said code. But, this code may not be sold without permission from me, and I would appreciate it if you would give me credit if you do use this code. Thank you!.

Welcome to my page. I hope you enjoy browsing around my collection of Mindstorms projects. As of yet I have posted a very few, but I will have an update for every new project in the future.

Thursday, July 21

Tuesday, July 19

Arduino powered Book light

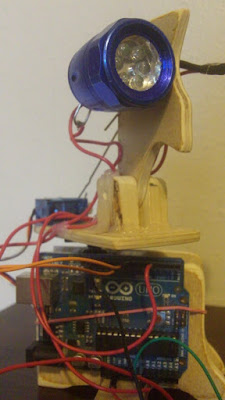

I am working on a book light right now. Sounds simple? Well I wanted to make something useful out of my Arduino and some hobby servos, so I thought of making a two axis flashlight platform, and the first use for it that occurred to me was a book light. An advanced Booklight. I might call it the Booklight 3000 or something impressive like that. Anyway, as a book light I wanted it to be able to follow the text that you are reading, so I devised a plan that would involve a light sensor. If I could get the flashlight to follow the light sensor, I could mount the sensor to a ring or something that you hold. This would be one of many applications like, for instance, an intruder light that flashes an alarm and wakes you up when the door or window gets opened.

Anyway, this is my first prototype of the Arduserve bot. I cut all the wood with a jigsaw and shaped it with one of the best multipurpose tools invented; the rotozip. I used two servo motors, the little blue one came with the kit I got the Arduino in, and the other I got from a friend. I put it all together with hot glue (gotta love that stuff,) and a couple nails. This project is fairly simple and fun to build and I might post the drawings and plans for how to build it if all you readers ask for them. Until next time - good.enough -

P.S. In the meantime, please check out my story, The Legoton Press.

Anyway, this is my first prototype of the Arduserve bot. I cut all the wood with a jigsaw and shaped it with one of the best multipurpose tools invented; the rotozip. I used two servo motors, the little blue one came with the kit I got the Arduino in, and the other I got from a friend. I put it all together with hot glue (gotta love that stuff,) and a couple nails. This project is fairly simple and fun to build and I might post the drawings and plans for how to build it if all you readers ask for them. Until next time - good.enough -

P.S. In the meantime, please check out my story, The Legoton Press.

Monday, May 9

My inactivity

I know that I have been inactive lately, and haven't posted anything new for months, but don't call me a quitter. I have just started College, and my time is filled with school. I wish I could continue, but for the present, I am too busy to write here. sorry. :(

Friday, February 11

Surveillance 202: Update 1

Well, you know the old 80/20 rule? Once you get eighty percent of a project you don't want to complete the last twenty percent. I found that to be the case in my line follower, and have put it on the back burner... for now. Anyway, I was inspired to build a fully automated video/still camera bot. It works great and as soon as I get some pictures, I'll put them on this post. But in the meantime, I would like to share what it does. First there is a process of positioning in which you manually assign all the coordinates that the robot will use in the rest of the program. You do this by moving the motors to the desired location, and, with a press of a button, the X and Y motor values are stored in an array. When you are done storing positions, you press another button, and the robot takes off on its own. The great thing about this method is: that the program is fully customizable to different rooms or locations, that you have an unlimited amount of picture locations ( basically unlimited, ) and the robot is very easy to build.

There are definitely some things that I want to change, most importantly, I want to be able to change a certain coordinate without having to go back and re-enter all of them. There are also innumerable extras that would be fun to add, such as a sound sensor to determine the loudest part of the room, and take most of the pictures there, or maybe a portrait taking program that would use an ultrasonic sensor to locate a person and take their picture. Well I'll leave it at that until I have more time. See Ya Back!!!

I have added a function to my code. It enables you to change existing parameters and even add new ones!

I am working on pictures right now so stay tuned!

void set_a_val()

{

PlayTone(1000, 100); Wait(100);

int c;

for(c = 0; ButtonPressed(3, true) == false; ){

ClearScreen();

NumOut(32, 50, c, false);

if(ButtonPressed(1, true) == true){

c++; until(ButtonPressed(1, true) == false); }

if(ButtonPressed(2, true) == true){

c--; until(ButtonPressed(2, true) == false); }

}

if(c > L) c = L;

else if(c < 0) c = 0;

if(c > S) S = c + 1;

until(ButtonPressed(1, true) == true);

PlaceX[c] = MotorTachoCount(OUT_A); PlaceY[c] = MotorTachoCount(OUT_C);

PlayTone(500, 100); Wait(200);

PlayTone(1500, 100); Wait(100);

}

P.S. I recognize that by posting my code to the public, I have given you the permission to use and modify to any extent the said code. But, this code may not be sold without permission from me, and I would appreciate it if you would give me credit if you do use this code. Thank you!.

There are definitely some things that I want to change, most importantly, I want to be able to change a certain coordinate without having to go back and re-enter all of them. There are also innumerable extras that would be fun to add, such as a sound sensor to determine the loudest part of the room, and take most of the pictures there, or maybe a portrait taking program that would use an ultrasonic sensor to locate a person and take their picture. Well I'll leave it at that until I have more time. See Ya Back!!!

I have added a function to my code. It enables you to change existing parameters and even add new ones!

I am working on pictures right now so stay tuned!

void set_a_val()

{

PlayTone(1000, 100); Wait(100);

int c;

for(c = 0; ButtonPressed(3, true) == false; ){

ClearScreen();

NumOut(32, 50, c, false);

if(ButtonPressed(1, true) == true){

c++; until(ButtonPressed(1, true) == false); }

if(ButtonPressed(2, true) == true){

c--; until(ButtonPressed(2, true) == false); }

}

if(c > L) c = L;

else if(c < 0) c = 0;

if(c > S) S = c + 1;

until(ButtonPressed(1, true) == true);

PlaceX[c] = MotorTachoCount(OUT_A); PlaceY[c] = MotorTachoCount(OUT_C);

PlayTone(500, 100); Wait(200);

PlayTone(1500, 100); Wait(100);

}

P.S. I recognize that by posting my code to the public, I have given you the permission to use and modify to any extent the said code. But, this code may not be sold without permission from me, and I would appreciate it if you would give me credit if you do use this code. Thank you!.

Wednesday, February 9

Line follower update 03

I've gotten the program pretty much worked out. I have only a few details to be worked out, but for now at least, all building has been put on the back burner as I am now focusing entirely on my schooling about seven hours a day seven days a week. speaking of which, I am supposed to be reading right now... well any way, I am going to post the whole program for ya'all now, so be ware!!!

#define ant(a) until(Button == a) Button = ButtonPressed(3, true)

#define sound(b); PlayTone(b, 50); Wait(100);

#define Move(c,d); { int T; OnFwdEx(OUT_A, d, false); if(c > 0) until( T > c ){ T = MotorTachoCount(OUT_A);} else until( T < c ){ T = MotorTachoCount(OUT_A);} }

bool alth, Go = true, Button = false, line = true;

bool where[] = {false, false, false, false, false};

//int turndeg[] = {-300, -150, 0, 150, 300};

int width = 0, line_position = 0, LLP = 0, thresh = 25;

int m = 0;

safecall int MAP(int input, int input_ref, int output_ref)

{ return (input * output_ref) / input_ref; }

bool AlterThresh(int T, int S, int L, bool AT){

if(T > S && T < L && AT == true){ thresh = thresh + 5; AT = true; }

else{ AT = false; } return AT; }

safecall void MOTOR_CONTROL(bool FB, int speed){

if(FB == true){ int turnpct = MAP(line_position, 100, 200) - 100;

RotateMotorEx(OUT_BC, speed, 90, turnpct, true, false);}

else RotateMotorEx(OUT_BC, -speed, 90, 0, false, false);}

task DISPLAY(){ while(Go == true){

SetSensorLight(IN_3);

TextOut(0, 57, "W", true); NumOut(10, 57, width, false);

TextOut(50, 57, "T", false); NumOut(60, 57, MAP(MotorTachoCount(OUT_A), 180, 100), false);

TextOut(0, 43, "P", false); NumOut(10, 43, line_position, false);

//TextOut(50, 43, "%", false); NumOut(60, 43, turnpot, false);

TextOut(0, 0, "L", false); NumOut(10, 0, m, false);

TextOut(25, 0, "LS", false); NumOut(38, 0, Sensor(IN_3), false);

TextOut(55, 0, "TH", false); NumOut(68, 0, thresh, false);

for(int c = 0; c < 5; c++){

if (where[c] == true) TextOut(c*10, 28, "O", false);

else TextOut(c*10, 28, "X", false);

}

Wait(100);

}}

task SCAN(){

SetSensorLight(IN_3);

int T = 0, pace = 50;

alth = true;

for(m = 0; Go == true;)

{

OnFwdEx(OUT_A, pace, false);

until( T > 180 || Sensor(IN_3) < thresh ){ T = MotorTachoCount(OUT_A);}

until( T > 180 || Sensor(IN_3) > thresh ){ T = MotorTachoCount(OUT_A);}

alth = AlterThresh(T, 160, 200, alth);

Move(pace, MotorTachoCount(OUT_A) + 10);

OffEx(OUT_A, false);

Wait(100);

OnFwdEx(OUT_A, -pace, false);

until( T < 1 || Sensor(IN_3) < thresh ){T = MotorTachoCount(OUT_A);}

until( T < 1 || Sensor(IN_3) < thresh ){T = MotorTachoCount(OUT_A);}

alth = AlterThresh(T, -200, 20, alth);

OffEx(OUT_A, false);

Wait(100);

if(alth == false && m == 0){thresh = thresh + 5; m = 1;}

}

}

task DATA_LOG(){

SetSensorLight(IN_3);

int end, sta;

while(Go == true){

bool FR = true;

int c = 0, now = CurrentTick();

until(Sensor(IN_3) < thresh){

if(CurrentTick() - now > 2000 && alth == false){ FR = false; MOTOR_CONTROL(false, 25); }}

if(FR == true) MOTOR_CONTROL(true, 50);

sta = MAP(MotorTachoCount(OUT_A), 180, 100);

sound(800);

until(Sensor(IN_3) > thresh);

end = MAP(MotorTachoCount(OUT_A), 180, 100);

sound(1000);

line_position = (end + sta) / 2;

if(sta > end) width = sta - end;

else width = end - sta;

for(;c<5;c++) where[c] = false;

// 0-25, 25-35, 35-65, 65-75, 75-100

if (line_position > 0 && line_position < 26) where[0] = true;

if (line_position > 25 && line_position < 50 - (width/2)) where[1] = true;

if (line_position > 50 - (width/2) && line_position < 50 + (width/2)) where[2] = true;

if (line_position > 50 + (width/2) && line_position < 74) where[3] = true;

if (line_position > 75 && line_position < 100) where[4] = true;

}

}

task main(){

RotateMotor(OUT_A, 35, -90);

ResetTachoCount(OUT_A);

Button = ButtonPressed(3, true);

while(true)

{

start DISPLAY;

start SCAN; sound(1500);

for(int c=0;c<5;c++) where[c] = false;

start DATA_LOG; sound(1500);

Button = ButtonPressed(3, true);

ant(true); sound(500);

ant(false); sound(1000); Go = true;

}

}

#define ant(a) until(Button == a) Button = ButtonPressed(3, true)

#define sound(b); PlayTone(b, 50); Wait(100);

#define Move(c,d); { int T; OnFwdEx(OUT_A, d, false); if(c > 0) until( T > c ){ T = MotorTachoCount(OUT_A);} else until( T < c ){ T = MotorTachoCount(OUT_A);} }

bool alth, Go = true, Button = false, line = true;

bool where[] = {false, false, false, false, false};

//int turndeg[] = {-300, -150, 0, 150, 300};

int width = 0, line_position = 0, LLP = 0, thresh = 25;

int m = 0;

safecall int MAP(int input, int input_ref, int output_ref)

{ return (input * output_ref) / input_ref; }

bool AlterThresh(int T, int S, int L, bool AT){

if(T > S && T < L && AT == true){ thresh = thresh + 5; AT = true; }

else{ AT = false; } return AT; }

safecall void MOTOR_CONTROL(bool FB, int speed){

if(FB == true){ int turnpct = MAP(line_position, 100, 200) - 100;

RotateMotorEx(OUT_BC, speed, 90, turnpct, true, false);}

else RotateMotorEx(OUT_BC, -speed, 90, 0, false, false);}

task DISPLAY(){ while(Go == true){

SetSensorLight(IN_3);

TextOut(0, 57, "W", true); NumOut(10, 57, width, false);

TextOut(50, 57, "T", false); NumOut(60, 57, MAP(MotorTachoCount(OUT_A), 180, 100), false);

TextOut(0, 43, "P", false); NumOut(10, 43, line_position, false);

//TextOut(50, 43, "%", false); NumOut(60, 43, turnpot, false);

TextOut(0, 0, "L", false); NumOut(10, 0, m, false);

TextOut(25, 0, "LS", false); NumOut(38, 0, Sensor(IN_3), false);

TextOut(55, 0, "TH", false); NumOut(68, 0, thresh, false);

for(int c = 0; c < 5; c++){

if (where[c] == true) TextOut(c*10, 28, "O", false);

else TextOut(c*10, 28, "X", false);

}

Wait(100);

}}

task SCAN(){

SetSensorLight(IN_3);

int T = 0, pace = 50;

alth = true;

for(m = 0; Go == true;)

{

OnFwdEx(OUT_A, pace, false);

until( T > 180 || Sensor(IN_3) < thresh ){ T = MotorTachoCount(OUT_A);}

until( T > 180 || Sensor(IN_3) > thresh ){ T = MotorTachoCount(OUT_A);}

alth = AlterThresh(T, 160, 200, alth);

Move(pace, MotorTachoCount(OUT_A) + 10);

OffEx(OUT_A, false);

Wait(100);

OnFwdEx(OUT_A, -pace, false);

until( T < 1 || Sensor(IN_3) < thresh ){T = MotorTachoCount(OUT_A);}

until( T < 1 || Sensor(IN_3) < thresh ){T = MotorTachoCount(OUT_A);}

alth = AlterThresh(T, -200, 20, alth);

OffEx(OUT_A, false);

Wait(100);

if(alth == false && m == 0){thresh = thresh + 5; m = 1;}

}

}

task DATA_LOG(){

SetSensorLight(IN_3);

int end, sta;

while(Go == true){

bool FR = true;

int c = 0, now = CurrentTick();

until(Sensor(IN_3) < thresh){

if(CurrentTick() - now > 2000 && alth == false){ FR = false; MOTOR_CONTROL(false, 25); }}

if(FR == true) MOTOR_CONTROL(true, 50);

sta = MAP(MotorTachoCount(OUT_A), 180, 100);

sound(800);

until(Sensor(IN_3) > thresh);

end = MAP(MotorTachoCount(OUT_A), 180, 100);

sound(1000);

line_position = (end + sta) / 2;

if(sta > end) width = sta - end;

else width = end - sta;

for(;c<5;c++) where[c] = false;

// 0-25, 25-35, 35-65, 65-75, 75-100

if (line_position > 0 && line_position < 26) where[0] = true;

if (line_position > 25 && line_position < 50 - (width/2)) where[1] = true;

if (line_position > 50 - (width/2) && line_position < 50 + (width/2)) where[2] = true;

if (line_position > 50 + (width/2) && line_position < 74) where[3] = true;

if (line_position > 75 && line_position < 100) where[4] = true;

}

}

task main(){

RotateMotor(OUT_A, 35, -90);

ResetTachoCount(OUT_A);

Button = ButtonPressed(3, true);

while(true)

{

start DISPLAY;

start SCAN; sound(1500);

for(int c=0;c<5;c++) where[c] = false;

start DATA_LOG; sound(1500);

Button = ButtonPressed(3, true);

ant(true); sound(500);

ant(false); sound(1000); Go = true;

}

}

Wow! If anyone has suggestions or comments, feel free to type, I am always looking for advice! Also, be sure to check out my other blog the Legoton Press. You can get there by clicking on "view complete profile" over on the right.

P.S. I recognize that by posting my code to the public, I have given you the permission to use and modify to any extent the said code. But, this code may not be sold without permission from me, and I would appreciate it if you would give me credit if you do use this code. Thank you!.

Sunday, January 30

Line follower update 02

I have gotten far on my program, and will post a screen-shot for you now. Just a minute... Ok, here it is:

Well, that is all for now... I'd better get back to programming!

P.S. I recognize that by posting my code to the public, I have given you the permission to use, modify to any extent the said code. But, this code may not be sold without permission from me, and I would appreciate it if you would give me credit if you do use this code. Thank you!

First page out of three!

As you can see, the layout is quite messy. I have too many global variables, most of which task DISPLAY() is using. I think that I will turn DISPLAY() into a function that is called by the other two main tasks. If you will notice, the screen-shot shows only one third of the code I have written. That is too much code for a simple line follower, but as I get each part perfected, I hone it down. For example: The function MOTOR_CONTROL(), was at first a complicated task, but as I saw that I only wanted it to run after a certain part of task DATA_LOG(), I converted it into a function. This conversion enabled me to eliminate a few global variables that were used only by MOTOR_CONTROL(), substituting them for parameters.Well, that is all for now... I'd better get back to programming!

P.S. I recognize that by posting my code to the public, I have given you the permission to use, modify to any extent the said code. But, this code may not be sold without permission from me, and I would appreciate it if you would give me credit if you do use this code. Thank you!

Tuesday, January 18

Building a Line follower. Easy?

Ok, I guess that from my last post I sounded pretty much an expert on the whole line following thing... well ever since then I've been working on a follower myself, and I'll tell you what, it ain't easy. I find myself in the lower end of "the middle class of programmers" which I established in my last post. (Those who understand the basics and essentials of programming, but have not mastered the art.) I finished the robot in a few hours, but I've made, and rejected, three complex programs each of which I spent considerable time designing. I am now on my fourth, I decided to do it in NXC because I was running out of file space on my NXT when using NXT-G. So far, I haven't got quite as far as I did in NXT-G, but I had to overcome many obstacles and bugs (not being very fluent in NXC.) I will be posting updates on my robot as well as code snippets as I get them finished.

Monday, January 10

Line Following

|

| Continuous Line Follower |

|

| Four Light Sensors |

There are many other alternatives to the methods of line following described above, one being to buy non-lego sensors for your robot such as the five sensor array below. One alternative that I have thought of is to have a light sensor mounted on an arm or boom and swing back and forth in front of the robot. The light sensor would detect the line edges and, depending on the position of the servo controlling it, the NXT could tell how hard to turn, and what direction to turn.

There are many other alternatives to the methods of line following described above, one being to buy non-lego sensors for your robot such as the five sensor array below. One alternative that I have thought of is to have a light sensor mounted on an arm or boom and swing back and forth in front of the robot. The light sensor would detect the line edges and, depending on the position of the servo controlling it, the NXT could tell how hard to turn, and what direction to turn. The algorithm used to decide the turn would run something like this.

#define RIGHT true;

#define LEFT false;

{ // when pointed straight ahead, the rotation sensor is at zero.

int turnpct = degrees / 2;

if (degrees > 0){ direction = RIGHT; }

else if (degrees < 0){ direction = LEFT; }

RotateMotorEx(BC, 100, 90,

turnpct, true, false);

}// I have not tested this algorithm.

//I made it up as I was sitting here,

//but it is something like that which you would use.

|

| The GreyHound |

The main advantage of such a design is:

Although a little slower than using multiple light sensors, the 'sweeping' method is much more accurate, providing the ability to get a reading on every degree that the motor controlling it is able to turn to.

For example, say that we have four different light sensors across the front of our robot similar to what we see in the third picture up. We could get four readings. We could vaguely tell how wide the line is, and generally where it is in respect to the front of the robot. Now let's say that the line our robot is trying to follow is wide enough to fit one light sensor. The robot randomly picks one of the middle sensors (we'll call it Jared.) Now on following the line, the robot tries to keep the line under the chosen sensor (Jared,) and when Jared losses the line, the two other sensors start checking for it in order to alert the NXT as to where it is. On receiving information as to the direction the line has turned, the NXT gives the appropriate information to the drive motors who respond accordingly. This sounds great, but there are two problems to this method. If the line turns too sharply, the robot loses it, and upon adjusting the turn radius, the bot follows the line in zig-zags thereby considerably reducing its speed.

If we use the sweeping method however, our results are much more promising. The light sensor (we'll continue using the name Jared for familiarities sake,) goes back and forth across the line, stopping precisely at the edges so as not to get confused with any other lines that may be in the near vicinity. Every time Jared gets to one edge of the line, he informs the NXT, who in turn, gets the motor degrees from the motor moving Jared. After receiving two such motor positions, the NXT finds the average, ( the middle of the line, ) and adjusts the turn percent accordingly. When our robot comes to a corner, it slows down so as to not overrun and get lost.

To sum it all up, the sweeping method of line following is slower going in a straight line because of the time taken to move the sensor, but because of the added locations possible for the sensor to be in, the robots precision is greatly advanced and therefore the speed and smoothness in traversing curves surpasses greatly the performance of other robots.

Saturday, January 1

4 DOF mobile robotic arm

Have you ever tried to build a big robot, so big that you'd need multiple brains and definitely multiple power sources? Well, up to now I have wanted to, but I did not have all the pieces, motors, and ways to control them.

For maybe a year I have gotten close to big because of the amount of Legos I had obtained, but I still wasn't quite there. This year for my birthday I received an Arduino and decided to use it for a second motor controller. Since the Arduino can provide five volts only, I used it to manipulate the servos controlling the pneumatic switches.

Now, this may seem great, but after putting it all together, the parts I still needed coming in the mail, I ran the quick test program I always do (to work out the last details,) and realized something important. Even though I had geared the motors down, they were not moving... the robot was just too heavy. I decided to remodel using worm gears this time to see if I could get any movement at all. Now that that is done, it is all moving smoothly, though extremely slowly.

After witnessing the extreme slowness produced by the heavy-ness of my machine, I decided to do a bit of research on NXTLog to see if anybody had gotten a large and complex robot to go very fast at all. It seems that nobody has... at least, I did not see any body getting a robot with as many motors and all in all weight as my bot to traverse with any speed to talk about. Well that is interesting, I wonder if there are any other, more powerful motors for cheap that could be adapted for use in a Lego robot.

for more pictures of my Mobile Robotic Arm, click HERE.

For maybe a year I have gotten close to big because of the amount of Legos I had obtained, but I still wasn't quite there. This year for my birthday I received an Arduino and decided to use it for a second motor controller. Since the Arduino can provide five volts only, I used it to manipulate the servos controlling the pneumatic switches.

After witnessing the extreme slowness produced by the heavy-ness of my machine, I decided to do a bit of research on NXTLog to see if anybody had gotten a large and complex robot to go very fast at all. It seems that nobody has... at least, I did not see any body getting a robot with as many motors and all in all weight as my bot to traverse with any speed to talk about. Well that is interesting, I wonder if there are any other, more powerful motors for cheap that could be adapted for use in a Lego robot.

for more pictures of my Mobile Robotic Arm, click HERE.

Subscribe to:

Posts (Atom)